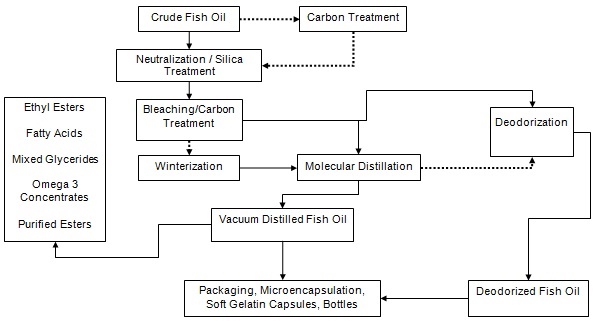

Typical commercial processing method for marine oils

All marine oils begin to go rancid when exposed to light, heat and/or air

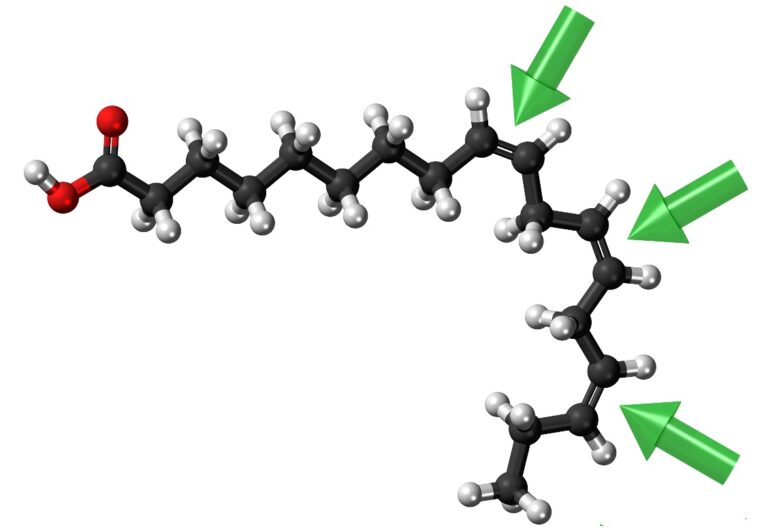

All polyunsaturated oils, but especially the long-chain fatty acids in marine oils are prone to free radical-producing oxidation, which cause the oil to become rancid. The long-chain fatty acids in fish, cod liver and krill oils, which are 5 times more sensitive than seed oils, begin to oxidize as soon as exposed to oxygen in air, metals, heat, and especially light, so oil needs to be processed by keeping these offenders away from the oil throughout production. Note that advanced oxidation will make a marine oil smell rancid, but the early stage oxidation has almost no aroma, and yet is still toxic.

It is essential that any marine oil process succeeds in the following two goals:

(1) Retains the integrity of the health beneficial (easily damageable) omega-3 fatty acids

(2) Avoids introducing health-damaging oxidized fatty acids (i.e. rancidity)

The process of producing a marine oil

Extract raw oil

Any of several methods may be used to extract oil from the fish trimmings (commonly heads and livers). High temperatures and/or pressure used for protein coagulation (separation) and subsequent oil release may partially modify the EFAs present, due to degradation reactions such as hydrolysis and oxidation:

• Cold-Pressing. Oil is removed under pressure involving temperatures under 140°F

The trimmings from the filleting process (mostly the heads and livers) are cooked (usually with steam) and then it is screened and pressed to separate protein solids from liquid. The oil is obtained by filtering the liquid to separate it from the water content.

• Solvent extraction. Oil is extracted using a solvent. E.g. hexane, acetone

• Supercritical fluids. Emerging technology uses solvents, usually CO2, which does not remain in the product, returning to gas state and evaporating at room temperature and pressure; process involves a moderate temperature, oxygen-free environment. Extraction of low polarity lipids avoids the need to extract impurities. High cost.

• Fish silage. A semi-liquid product made from whole or parts of fish, to which acids, enzymes, or lactic acid bacteria are added, causing protein hydrolysis. Low temperature, no solvents.

The extracted oil then typically undergoes a several step process to purify the oil and optionally concentrate its omega-3

Unless the oil has come from fish swimming in uncontaminated water, it will require purifying to remove insoluble impurities, phospholipids, free fatty acids, moisture, primary oxidation products, minerals, pigments and persistent organic pollutants (POPs). The refining process should be designed to retain the integrity of the PUFAs and other beneficial constituents of the oil (e.g. vitamins)

The first 3 steps remove some vitamins, but deodorization removes the most:

1. ALKALI REFINING

Removes free fatty acids and some metals.

2. BLEACHING.

Removes color substances, metals and dioxins. Uses clay or other natural earth absorbents.

3. WINTERIZATION (DESTEARINATION / REMOVE SATURATED FATS)

Cooled, then filtered or pressed, to remove stearins (saturated fats), usually to concentrate and clarify oil. Commonly uses solvents, such as hexane and acetone. Oils can be esterified with ethanol to produce ethyl esters, Esterification

We combine the fish oil with food grade ethanol to make fatty acid ethyl esters. This allows Omega-3 fatty acids to be separated from saturated fatty acids

4. DEODORIZATION

Steam distillation under vacuum removes unwanted odors. Also removes free fatty acids and most vitamins (E.g. vitamin A, D and E). Temperatures ?

Deodorization. Remove pesticides, PCBs. This cleaning step is done to ensure the oil has undetectable, or at least safe, levels of contaminants, since there are so few guaranteed, unpolluted waters. BTW, the infamous heavy metal contaminant, methylmercury, is water-soluble and may be present in fish flesh, but not so much in its oil. Deodorization usually removes most vitamin D and a lot of vitamin A.

5. DETOXIFICATION (TYPICALLY BY MOLECULAR DISTILLATION)

Heavy metals, including methymercury, PCBs, and other contaminants are removed from the oil via a molecular distillation process. Increasingly sophisticated forms of molecular distillation are being developed to detoxify marine oil by separating free fatty acids (FFAs), EPA and DHA fatty acids and contaminants, whilst protecting oil from oxidation and its formation of harmful peroxides.

Currently (2020), one of two detoxification methods is usually employed:

(i) Molecular distillation for separation of omega-3 fats, FFAs and toxins

The omega-3 fatty acids and toxins (fat-soluble contaminants, such as PCBs, dioxins, and pesticides) are separated by pulling the oil over a hot surface in a light-free, oxygen-free (high vacuum) environment, allowing the warmed oil molecules to condense on a cooled surface, before re-liquifying by colliding with other molecules. The goal is to keep the oil under 320 °F, the temperature at which trans fats begin to form. However, this process does significantly reduce the high levels of vitamins A and Din cod liver oil. Molecular distillation may also just be used for separation of fatty acids in the oil — it is not always used for removing contaminants.

(ii) Steam Flushing. Used by only a few companies, this method steam-cleans and flushes out contaminants in the oil in a light-free vacuum. This method employs a temperature of ~ 320°F (180°C). Steam flushing still removes some of the vitamin A and D content, but not as much as molecular distillation.

6. OMEGA-3 CONCENTRATION

Isolated EPA and DHA fatty acids are concentrated down to a desired level and ratio. Currently, there are 3 methods for doing this — further molecular distillation, enzymatic processing, or CO2 extraction. The purpose: to produce an omega-3 supplement that fits into a small capsule.

7. FORTIFIED

Natural or synthetic vitamins A and D may be added, to meet retailer’s standar